What Is the Difference Between Mica Band Heaters and Ceramic Band Heaters?

Home > Blog Archive > Category: Industrial Heating Technology > What Is the Difference Between Mica Band Heaters and Ceramic Band Heaters?

The Differences Between Band Heaters: Mica Bands vs Ceramic Bands

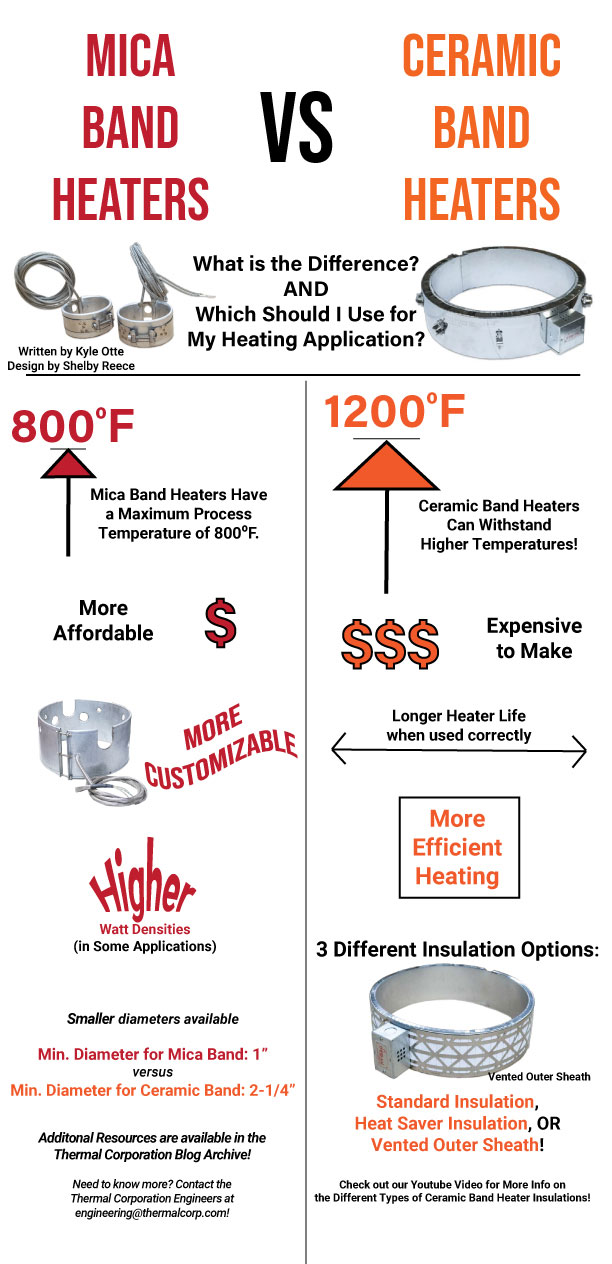

There are two types of band heaters that Thermal Corporation manufactures: mica band heaters and ceramic band heaters. There are strong points with each type, and the general differences are laid out below:

Temperatures

Ceramic band heaters can withstand a higher temperature than mica band heaters. Ceramic band heaters have a maximum operating temperature of 1200⁰F vs a maximum operating temperature of 800⁰F for a mica band heater.

Heater Life

Ceramic band heaters typically (but not always) have a longer life expectancy. This is due to the coiled resistance wire that is fed through ceramic blocks (called knuckles) vs. the thin resistance ribbon that is used in mica band heaters. The coiled resistance wire has a smaller ratio of surface area to internal cross-sectional area and thus doesn’t really oxidize and burn through as fast as the ribbon.

Watt Density

Mica band heaters can have a higher watt density than ceramic band heaters. Because the resistance ribbon in a mica band heater is tightly clamped between pieces of mica, there is better heat transfer from the ribbon to the exterior surfaces of the heater. Also, in general, mica band heaters will have less unheated area than a ceramic band heater, especially in smaller band heaters.

Customizability

Mica sheets can be cut into custom shapes and sizes, whereas ceramic band heaters are limited by the size of the knuckles. Because of this, mica band heaters are also much more customizable when it comes to dimensions. Ceramic band heaters are limited to 1/2″ width increments, whereas mica band heaters can be any width within the upper and lower limits of at least 1″ by 1″, depending on the specific mica band configuration.

Pricing

Ceramic band heaters are more expensive than mica bands. The ceramic knuckles are quite expensive when compared to the thin sheets of mica that mica bands are constructed from. However, this difference may be compensated for by the increased efficiency of the ceramic band heater.

Insulation Options

Standard ceramic band heaters have one layer of 3/8″ thick ceramic paper insulation over the knuckles, and then a stainless-steel outer sheath that reflects heat back into the process. The “Heat Saver” ceramic band insulation option has one layer of 1/8″ thick ceramic paper topped with a reflective stainless-steel sheath, and then an additional 2 layers of 3/8″ thick paper, topped by an additional sheath. All of this insulation yields a higher efficiency heater vs. a mica band heater. Ceramic band heaters also offer a “Vented Outer Sheath” option, seen in the image below. This allows heat to escape from the process, if needed for your application.

Closing Remarks

In conclusion, you just need to examine your heating process and specific needs for a band heater and decide between a mica band heater or a ceramic band heater. If we can be of any assistance, please let us know. Mica bands are cheaper, can have higher watt density, and are more easily customizable. Ceramic bands are more efficient, can withstand higher temperature, and generally last longer.

Have Questions?

Contact our engineers at (800) 633-2962 x152, or by email at engineering@thermalcorp.com.

Written by Kyle Otte

Edited by Shelby Reece

Date Published: 01.14.2020

Last Updated: 01.14.2020