Case Study #203: How to Test Thermocouples Inside a Mold

Home > Blog Archive > Category: Case Studies > Case Study #203: How to Test Thermocouples Inside a Mold

Case Study #203

Last year, we visited a customer to make recommendations on testing thermocouples mounted on a probe that was inserted into a mold. They wanted to test the thermocouple by measuring the resistance of the probe, so the machine did not have to be disassembled to check the thermocouple.

In this particular example, heater wires are stainless steel overbraid. Thermocouple wires are inside the hose. Probes are wrapped in aluminum foil before being inserted into a mold that is the size of a small car. Sometimes, the thermocouple is damaged while being inserted into the mold. The customer’s thought was to measure the resistance of the thermocouple after insertion as an indication of whether the thermocouple was good.

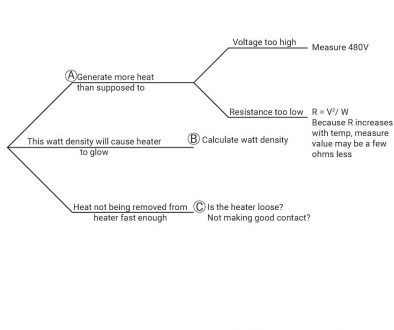

There are several problems with this approach:

- The first issue is that you are mostly just measuring the resistance of the wire. The thermocouple wire is metal, but it is not copper. So, the wire itself will have a relatively low ohms (maybe 5Ω to 25Ω or so, but not 1Ω to 2Ω like copper wire would be.)

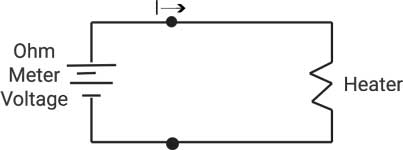

- The way an ohm meter measures a resistance is to place a voltage across the resistance and measure the current to calculate the resistance.

A typical circuit looks like this:

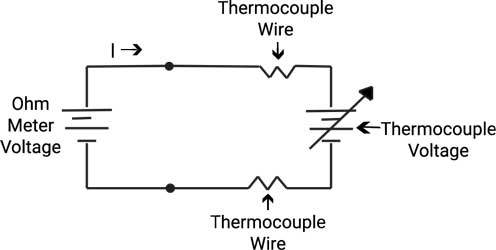

But, what we actually have in this example is this:

A thermocouple produces a temperature-dependent voltage as a result of the thermoelectric effect, and this voltage can be interpreted to measure temperature. Thus, the circuit shown above actually has two voltage sources. This second voltage will cause the ohm meter current to change, and the perceived resistance changes. However, the resistance of the thermocouple junction did not actually change. But, because the thermocouple voltage changed, the voltage across the resistance changed, producing a change in the resistance reading. Thus, the resistance reading may increase 20% or so. - When using a handheld multimeter, the accuracy is specified something like 15% ± x ohms. For a low resistance reading, the error can be substantial. These meters are designed for troubleshooting, not measuring precise low resistance measurements.

What we recommend:

Rather than a single dual thermocouple, use two single underbolt thermocouples placed 180° from each other at the tip. One thermocouple would be the control. To check the thermocouples, connect the second thermocouple to a handheld thermocouple reader. Then, two thermocouples should read essentially the same. It would be unlikely that the hose would be damaged on each one creating identical secondary junctions.

Written by Jim Dixon and Shelby Reece

Edited by Kyle Otte

Date Published: 07.15.2019

Last Updated: 09.03.2019