What is a Split Sheath Cartridge Heater?

Home > Blog Archive > Category: Industrial Heating Technology > What Is a Split Sheath Cartridge Heater?

So, what exactly is a Split Sheath Cartridge Heater?

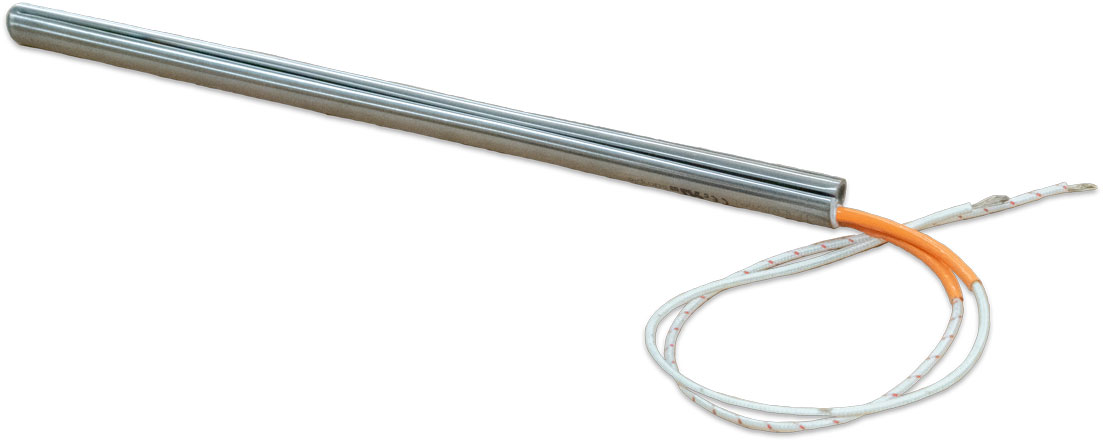

Spilt sheath cartridge heaters are tubular heaters that have been formed in to a half circle which is then folded in the middle with the two halves now making a circle. Their claim to fame is that they are easier to remove from a hole. This is true – but more on this later.

The drawings that usually accompany the advertisement show the two halves expanding as the heater heats up with the heater more completely filling the hole. The amount of expansion is actually a function of the thermal expansion of the metal sheath. Different metals expand different amounts, but all of the expansions are rather small, at least compared to the drawings, which are exaggerated for clarity. All of the sheath materials are either one of the stainless steels or incoloy steel.

The main point here is that a split sheath cartridge heater will expand the exact amount as a regular cartridge heater made of the same steel. The amount of expansion is a function of the thermal expansion of the sheath and the diameter of the heater, which is the same for both types of heaters. Thus, they are the same.

Ease of Removal

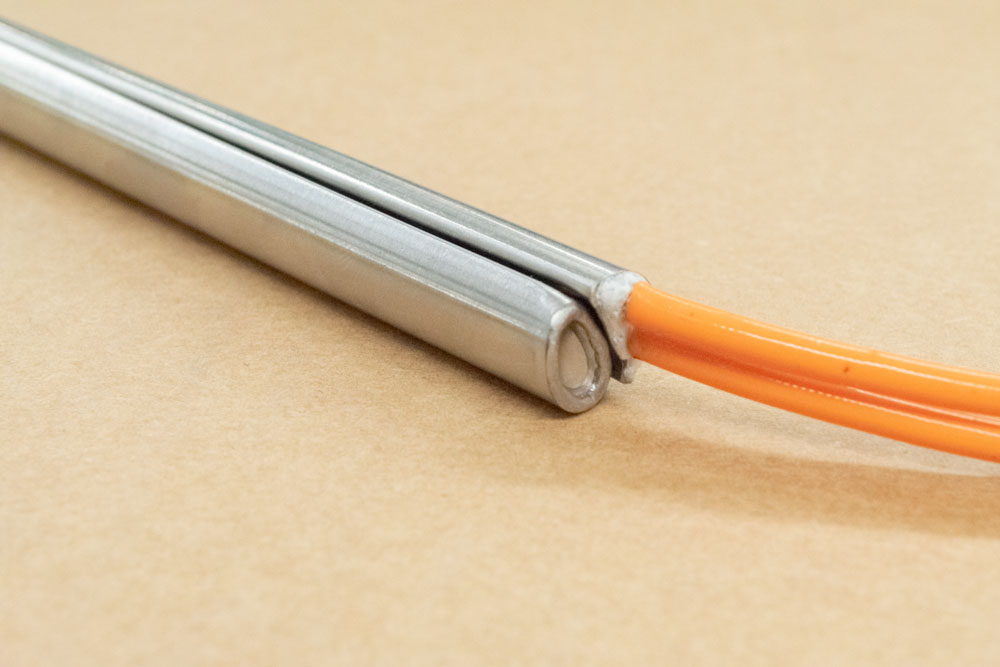

While it is possible to manufacture a heater in a near perfect circle, when you form the circle into a half circle it is not a near perfect half circle. When you put the two halves together, the resulting shape is slightly football shaped. That is, the diameter in one direction is not the same as the diameter if you rotate the measurement by 90 degrees. The difference is something on the order of 0.015 to 0.020 inches. What this means is that the AVERAGE diameter is smaller than a regular cartridge heater. THIS is why it is easier to remove. The smaller the diameter the easier the removal.

Disadvantages

With a slightly football shape, the heater is not making as good of contact with the hole and thus poorer heat transfer. The internal temperature of the heater will be higher and the heater will have shorter life.

Also, tubular heaters have more magnesium oxide insulation between the element wire that generates the heat and the inside of the sheath compared to a regular cartridge heater. This means the heater can more likely be run in air because of the higher breakdown due to the thicker MgO, but also means that this thicker insulation reduces the rate of heat transfer. Again, poorer heat transfer means that the heater will have a higher internal temperature and resulting shorter heater life.

Edited by Shelby Reece

Date Published: 07.19.2018

Last Updated: 09.09.2019