Case Study #167: Heating Too Slow? Check Your Process Set-Up

Home > Blog Archive > Category: Case Studies > Case Study #167: Heating Too Slow? Check Your Process Set-Up

Case Study #167

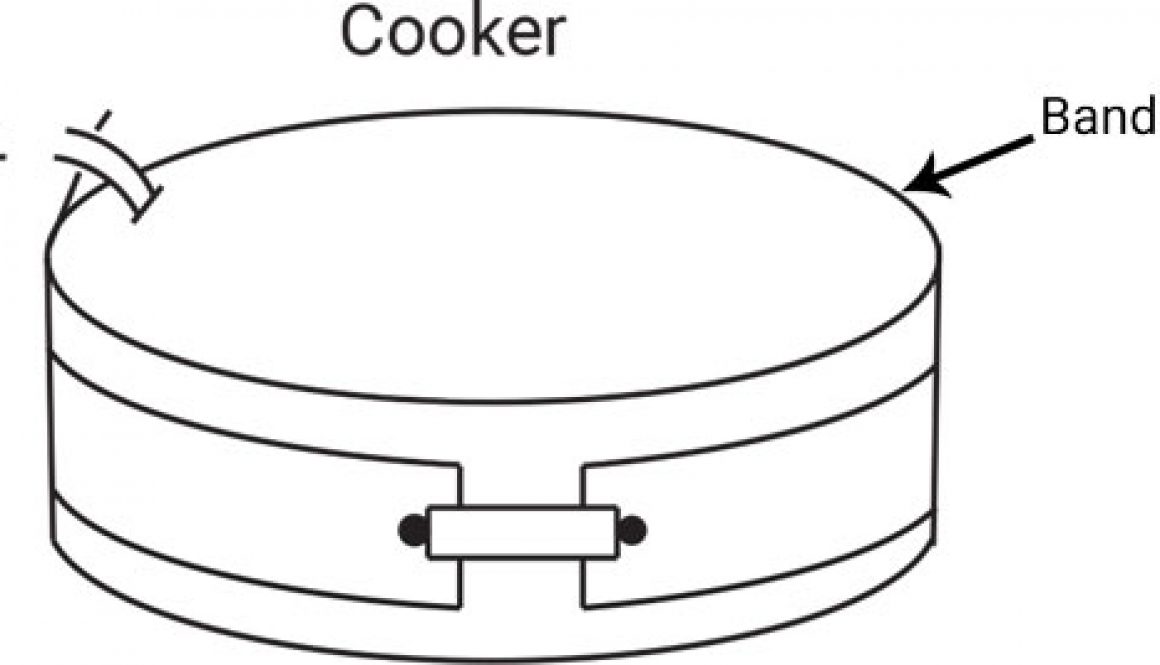

I once worked with a customer that manufactured flexible fishing lures. They had two set-ups for creating the lures- an old system and a new system. The two systems were virtually identical except for the fact that the newer system, for which they purchased a band heater, heated up too slowly.

Initially, I was led to believe that they were using a two-piece mica band heater. If they had been using a two-piece heater, I would have suspected that the heater was wired incorrectly. There are two ways to verify this.

Two Ways to Determine if a Two-Piece Heater is Wired Incorrectly

- Measure the voltage across each heater half. The voltage on each half should match the stamp on the heater. This particular heater was a 120V heater. So for this case, they should both have read 120V. If 60V was read, then the heaters were wired in series rather than in parallel. This is a common issue we see. (See our blog post on “Should Your Heaters Be Wired in Parallel or in Series?” for more information on this topic.) If the voltage is half of the correct voltage, the wattage output will be 25% of the stamped wattage.

- Visually inspect the wiring. One terminal, or lead, of each heater half should be tied to the black 120V wiring. The other end of the heater half should be connected to the “white” neutral wiring.

If the heaters measured the correct voltage, what would you check next?

Turn off the power and disconnect the power leads going to one end and measure the resistance of each heater half. The resistance should be approximately: R = V2 / W

In this case, the voltage (V) was 120V, and the wattage (W) was 1500W as stamped on the heater.

HOWEVER, I found out that this was a one-piece heater and not a two-piece heater. Therefore, what should I check first? If you said, the heater resistance, then you are correct. Before I made this measurement, I asked the following question: Was the LED light on the controller ON all the time?

Why did I ask this question?

The light was ON all the time. If the light was not ON all the time, then the heater was not turned on the entire time as the process heated. This would indicate a possible programming error with the temperature controller.

When I talked to a technician at the customer’s plant, it was mentioned that the temperature controller indicated that the temperature quickly went to 380°F, but the actual process took about 20 to 30 minutes to get hot. I asked the customer to describe the process in more detail. What would I see if I was at the plant looking at the process?

The Heating Process

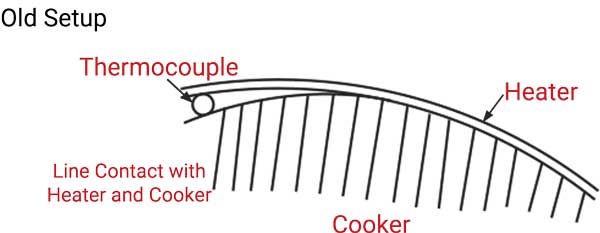

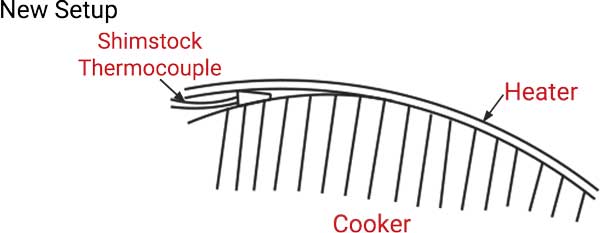

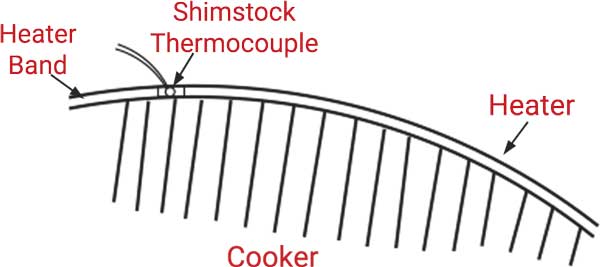

The heating process was described to me as such: the heater and thermocouples were covered in fiberglass. On the older system, a thermocouple probe is slipped under the edge of the heater. On the new system, a shimstock thermocouple is slipped under the edge of the heater.

The thermocouple probe only has one line contact with the heater and the cooker, like this diagram:

Who knows for sure what was being measured?

Now that the customer is using a shimstock thermocouple, it might look like this:

It may very well be that the shimstock thermocouple is primarily measuring the heater temperature. In any case, both of these configurations are very poor setups.

The Thermal Corporation Recommendation

We recommended that they place the shimstock thermocouple in the heater gap, up against the cooker. Then, place some high-temperature insulation on top of the thermocouple so when the band is tightened, the strap screw would push the thermocouple up against the cooker securely. This ensures the temperature sensor is measuring the cooker temperature, not just the temperature of the heater.

After these changes were applied to the customer’s process, it corrected their problem, and looked something like this:

Written by Jim Dixon and Shelby Reece

Edited by Kyle Otte

Date Published: 11.05.2019

Last Updated: 11.05.2019