Home > Products > Mica Band Heaters

Mica Band Heater Quote

Click Each Tab for more information

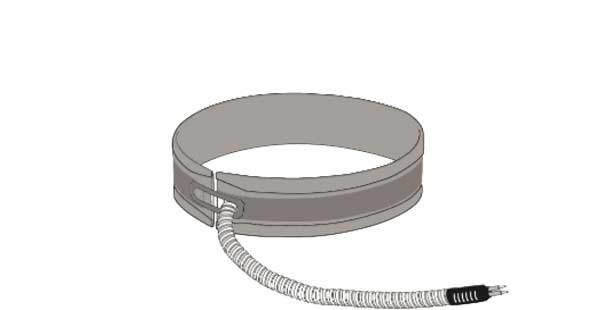

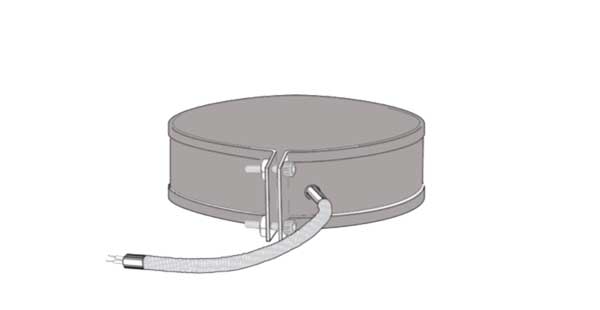

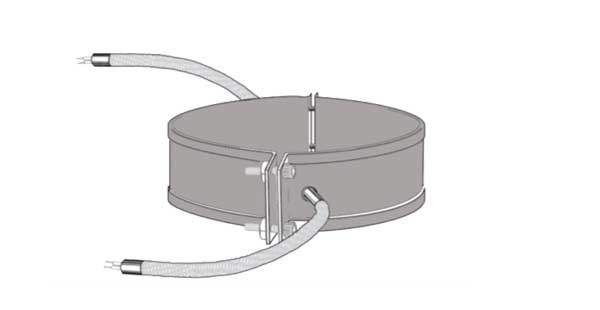

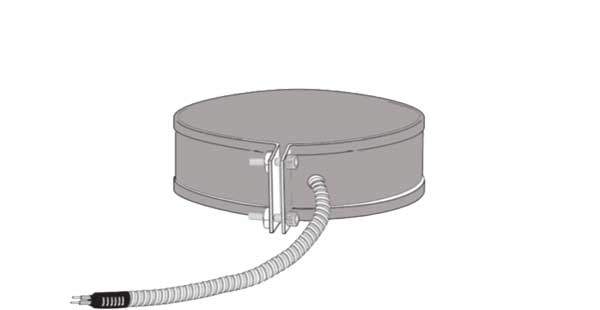

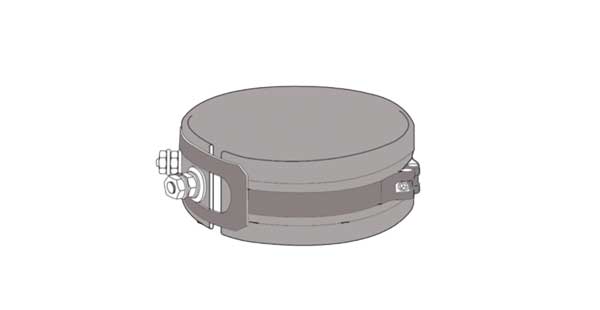

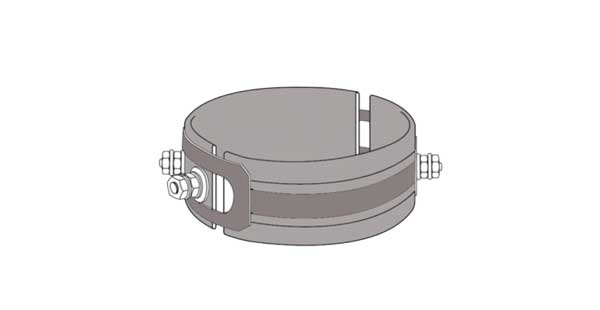

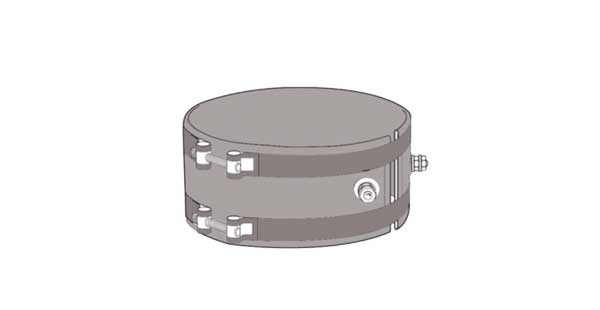

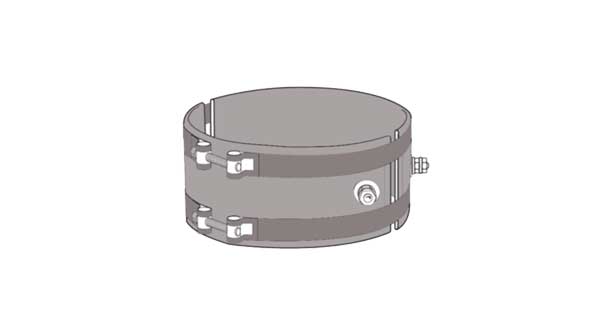

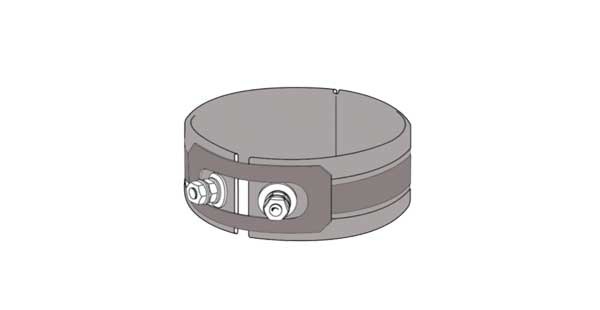

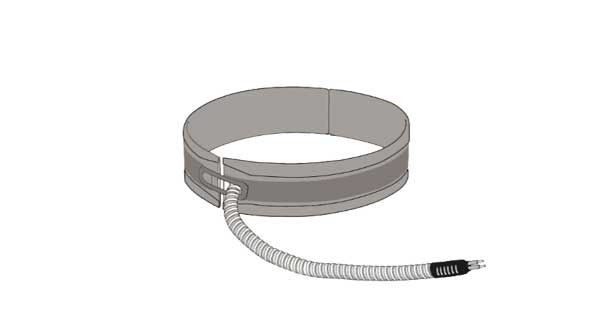

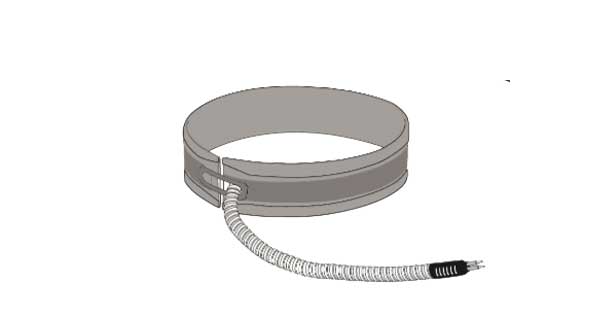

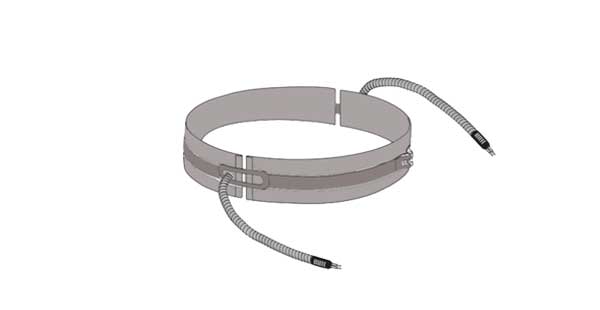

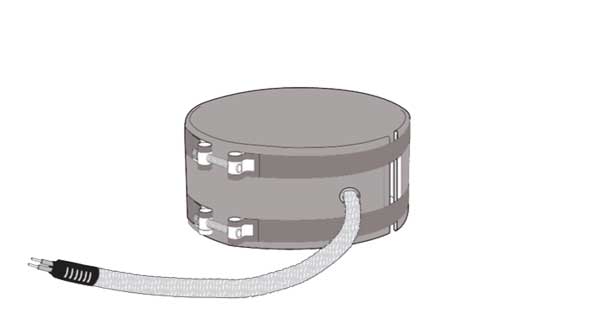

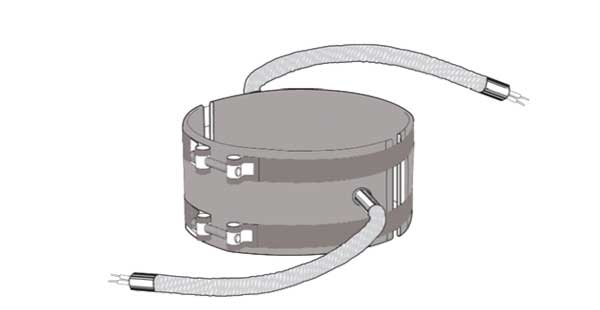

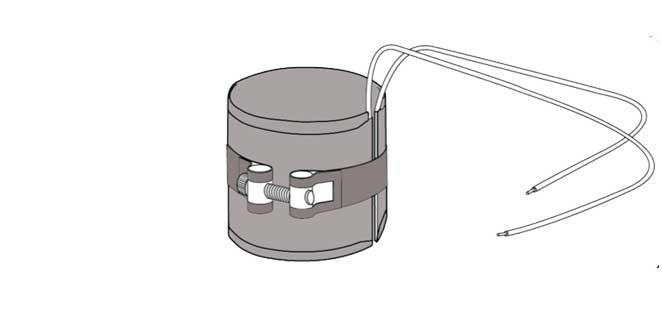

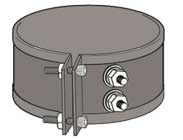

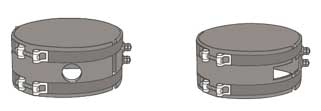

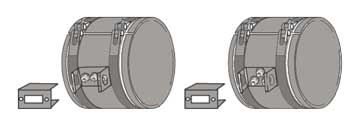

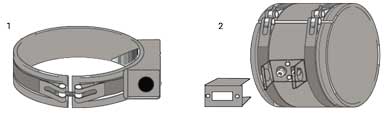

Standard Configurations

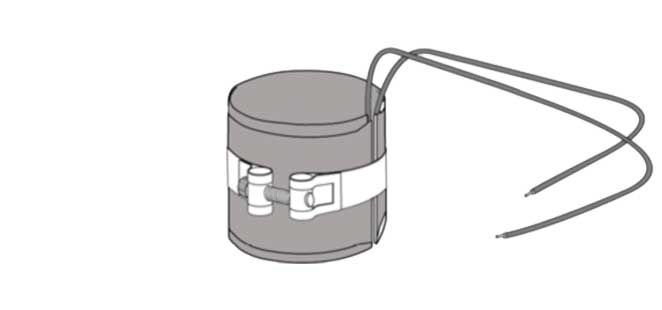

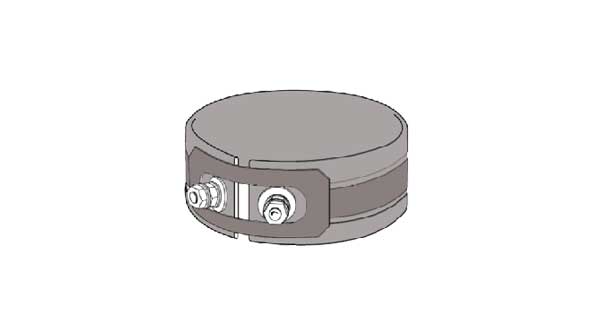

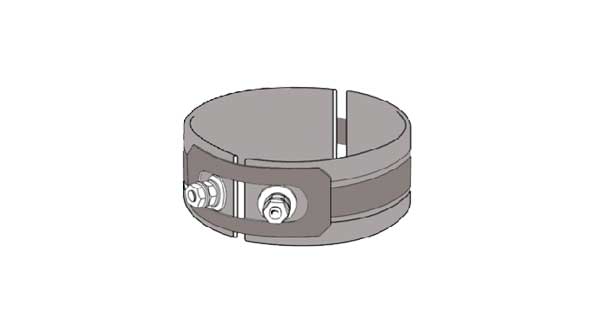

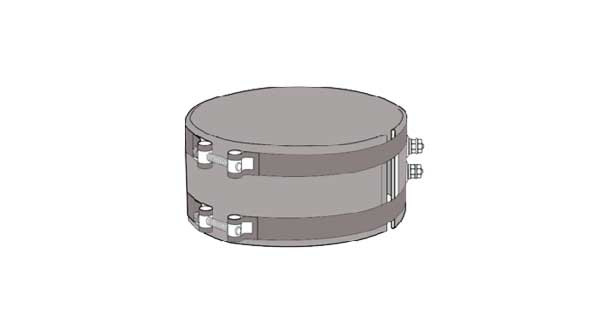

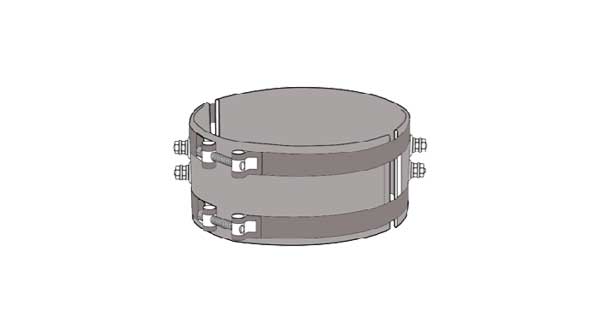

- Post Terminals with Straps

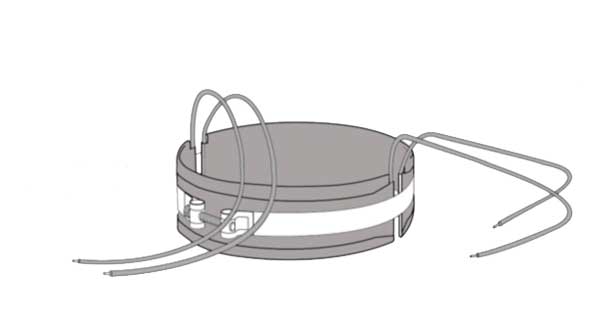

- Post Terminals with Flanges

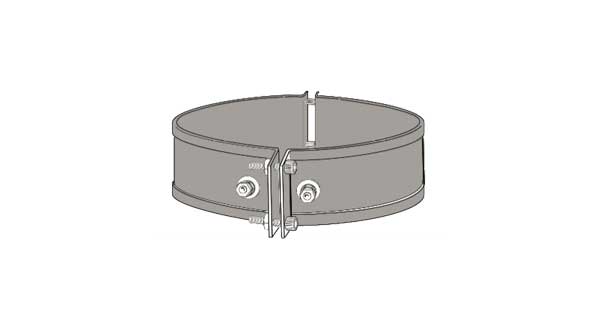

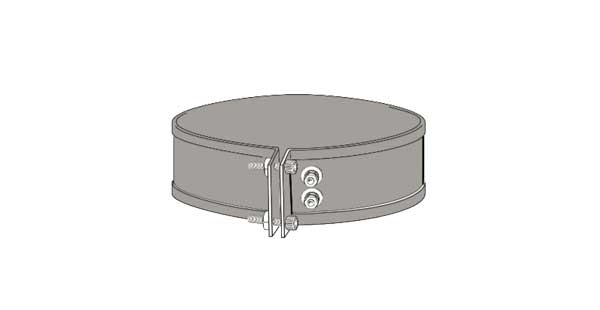

- Lead Wires with Straps

- Lead Wires with Flanges

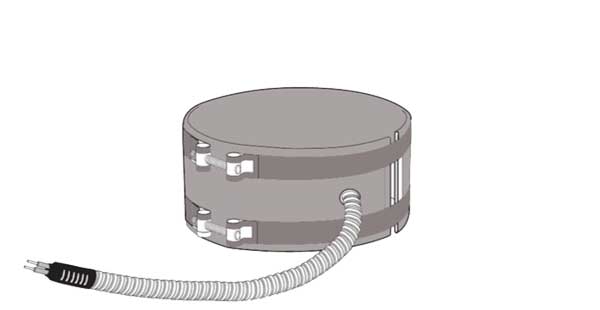

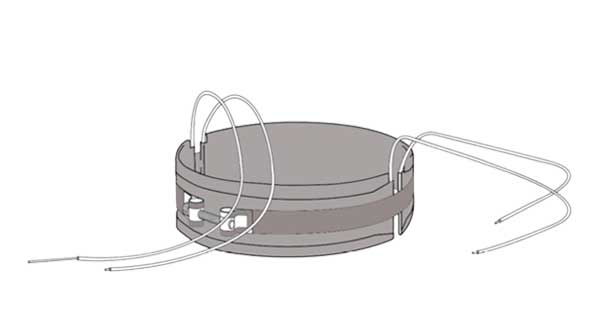

Thermal Corporation designs and manufactures mica band heaters. Each mica band heater is manufactured to your specifications and can be shipped as quickly as many off the shelf heaters, when needed. Mica band heaters are used to heat cylinders such as the barrels and nozzles of plastic injection and extruding machines.

Ready to Order? Click here to request a quote for a Mica Band Heater!

Just select Mica Band Heater in the “Select a Product” section. Pricing starts at $34.97.

Advantages of Mica Band Heaters:

- High watt-density capabilities

- Reasonably high temperature capabilities: 700°F

- Good efficiency

- Good lifetime

- Low cost

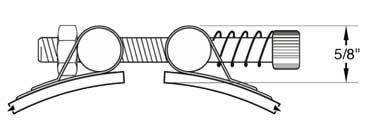

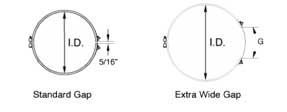

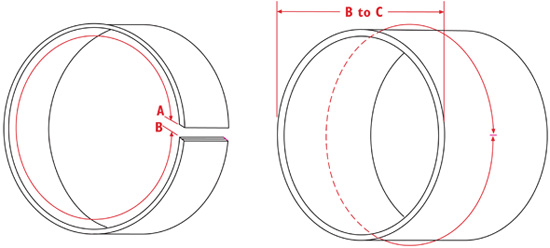

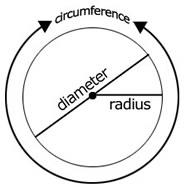

After locating a mica band heater configuration from our mica band configuration list, determine the diameter of the part you want to install the heater on.

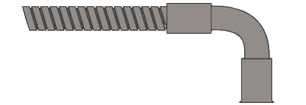

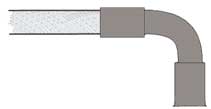

Hopefully, you can get this information from a drawing, but if not, you can refer to the above graphic and easily make your own measurement (We only need one of the dimensions). Next, determine the width of the heater and the length of the lead wire if appropriate.

After that, specify the wattage and the available voltage and you are ready to go! If there are holes or notches in your band heater, click here for more information on how to measure your mica band heaters.

Have any questions?

Contact Customer Service by phone at (800) 633-2962, by email at sales@thermalcorp.com, or chat with us using our chat feature located at the bottom right of the page!

| Band Heater Specifications | |

|---|---|

| Width | ± 1/16″ |

| Finished Diameter | ± 1/32″ |

| Wattage at Design Voltage | +5% – 10% |

| Standard Gap Size for 1 Piece Heater | 5/16″ |

| Standard Gap Size for 2 Piece Heater | 3/16″ |

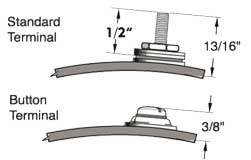

| Standard Terminal Height | 13/16″ |

| Low Profile Standard Terminal Height | 3/8″ |

| Lead Length Tolerances | ± 1" up to 72" ± 2% over 72" |

_______________________________________

Check Your Barrel or Nozzle Surfaces

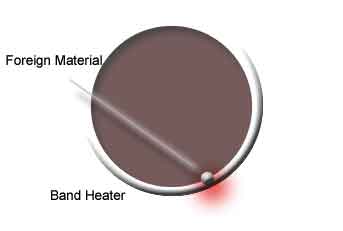

When replacing a mica band heater assure that the barrel or nozzle is free of material, smooth and clean.

A rough spot or foreign material on the barrel can greatly reduce the life of your mica band heater. A small particle can leave an air gap on either side of itself which can cause a “hot spot.”

Air will not conduct the heat away from your heater as fast as the metal of the barrel. This results in a spot on the heater where the temperature will be significantly hotter than the rest of the heater. Just a 0.005″ air gap on a typical 30 watts per square inch heater will cause that spot to run 250 degrees (F) hotter!

_______________________________________

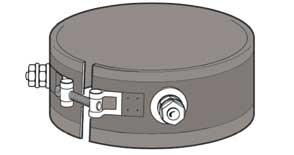

The Tighter, The Better

After installing a new mica band heater, we suggest that you come back to it after fifteen minutes of operating time. After proper actions are taken to assure there is no power going to the heater and that the heater will not cycle on, re-tighten your straps or clamping mechanism.

Make a habit of checking the tightness of the band heater periodically and you will be surprised at how you can increase the life of your band heaters.

_______________________________________

Fewer Holes, Longer Life

Every time you add a hole to a mica band heater, you give another avenue for Contaminants to enter the heater. You also add expense and often add to the delivery time.

If the hole is for a thermocouple or other instrument, you can often order a heater with a larger gap to accommodate the thermocouple. Another option if the band heater has several holes along the circumference of the heater is to use two heaters instead of one. For instance if you are using a six inch wide heater with several one inch holes, you might try using two heaters that are 2.5″ wide.

Call us at (800) 633-2962 and speak with one of our customer service reps or email us at sales@thermalcorp.com if you’d like some help in trouble-shooting your mica band heaters problems.

_______________________________________

Use the Right Parts

If your mica band heaters has post terminals, make sure you are using high temperature ring terminals. Standard ring terminals will cook to the point they become brittle and can easily break causing a short. You can find high temperature wire and ring terminals on our general accessories page.

If your mica heater bands or strip heater terminations are not covered with a terminal box, consider using ceramic terminal covers. Dust, material or other contaminates can build quickly on and around the connections eventually carbonizing which will short the mica heater bands and cause downtime.

_______________________________________

Related Blogs

What Is Watt Density and How Is It Related to Heater Life?

Tips for Extending the Life of Band Heaters

What Is Wrong with This Band Heater Request?

How Much Wattage Is Needed for a Heater? (video blog)

What Is the Difference Between Mica Band Heaters and Ceramic Band Heaters?

How To: Extend the Life of Band Heaters (video blog)

How To Measure a Band Heater (video blog)

Written by Jennifer Taylor & Shelby Reece

Date Published: 05.21.2014

Last Updated: 03.11.2020