Case Study #175: The Glowing Orange Band Heater

Home > Blog Archive > Category: Case Studies > Case Study #175: The Glowing Orange Band Heater

Case Study #175: The Glowing Orange Band Heater

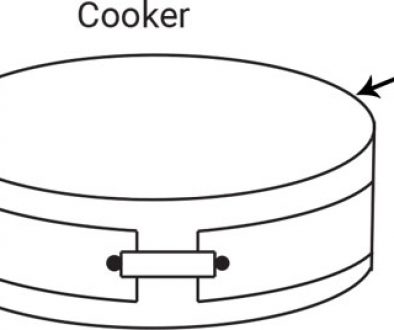

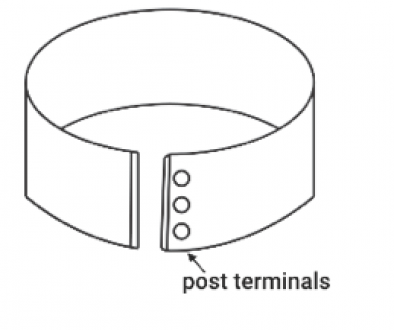

A customer ordered a mica band configuration 528 that was 9.55 inches in diameter and 1.5 inches wide. The heater was rated at 2,000W, 480V. The customer asked that the post terminals be moved so an incorporated strap could be used.

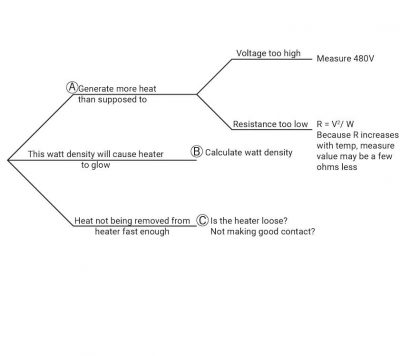

The application required that the heater have 1/2″ nickel return ribbon and an extra layer of mica inside the heater. The recommended wattage was 1,200W, yet the customer ordered a 2,000W heater. The customer called in and mentioned that the heater glowed orange hot and he wasn’t sure why. Immediately, I knew this was because the heater was getting well over 1,000 degrees F. But, why? See the diagram below.

The first thing I suspected was watt density. Watt density is calculated as follows:

Heated Width = 1-1/2″ – 1/4″ – 1/4″ = 1″

Heated Length = 29-1/4″ – 1-7/8″ = 27-3/8″

Heated Area = 1″ x 27-3/8″ = 27-3/8″ in2

Watt Density = 2,000W / 27-3/8 in2 = 73 Watts/in2

This is about twice what it should be! This is why it was orange hot, but what can we do to fix this issue? There are two options:

A. Increase Heated Area

B. Reduce Wattage

This is how I handled it:

- I asked the customer about possibly increasing width. The customer said we could go to 1-3/4″ wide. We also talked about possibly converting to a configuration 500 heater which would remove the 1-7/8″ circumference length used for the post terminals. This would also remove the 1/2″ nickel return ribbon and a layer of sandwich mica.

- I, then, asked the customer how they came up with 2,000W for their quoted heater. The customer said that this was the wattage on a ceramic band heater they had used in that place beforehand. This did not line up, however, because ceramic band heaters start to fail around 40 Watts/in2.

- My next question surrounded whether the customer was using PID control and he said yes. I asked him to measure the on-time and off-time and calculate the percentage of time the heater was on, using this formula:

on-time / (on-time + off-time)

He calculated 75%. I asked him if that was the exact calculated number or if he had read it off of the control panel. He, then, told me that he was able to set it to any percent he desired. That was my AHA!-moment. This was not PID Control, it was a percentage timer. He thought he was able to operate on even less! 75% of 2,000W is 1,500W.

After all of our discussion, the customer decided to try a similar-style heater with a 1-3/4″ width and 1,500W. The heated area would now be:

Heated Width = 1-3/4″ – 1/4″ – 1/4″ = 1-1/4″

Heated Area = 1-1/4″ x 29-1/4″ = 35.56 in2

Watt Density = 1,500W / 36.56 in2 = 41 Watts/in2

This heater is much better than the first iteration of this heater. We provided the updated heater and the customer had no more problems.

Written by Jim Dixon

Edited by Shelby Reece and Kyle Otte

Date Published: 10.31.2019

Last Updated: 11.01.2019