Home > Products > Cartridge Heaters

Cartridge Heater Quote

Click Each Tab for more information

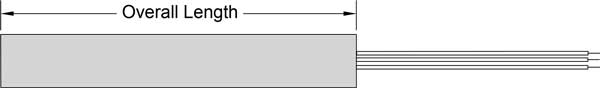

Cartridge heaters by Thermal Corporation are high temperature swaged units manufactured with magnesium oxide insulation. Every cartridge heater by Thermal Corporation is a premium quality unit with an incoloy sheath which offers a higher temperature rating and higher resistance to chemical corrosion. Please see our cartridge heater configurations page to view a selection of the more commonly used styles available for quick manufacturing to your specifications.

Have any questions?

Contact Thermal Corporation at 800-633-2962 or by email at sales@thermalcorp.com for information or specifications not described in the text below.

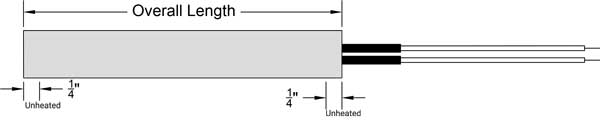

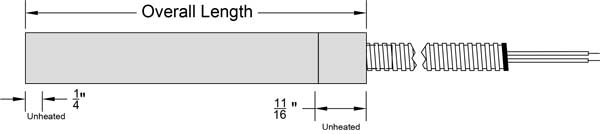

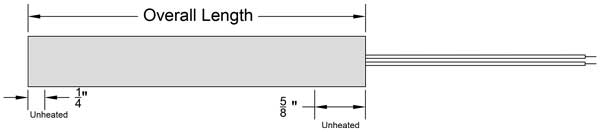

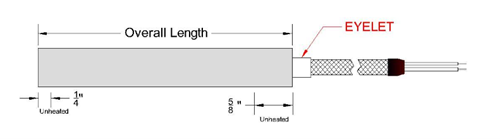

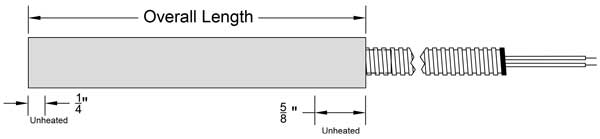

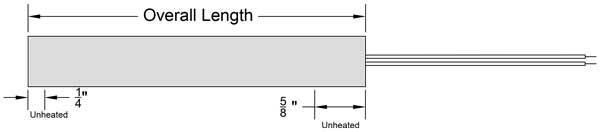

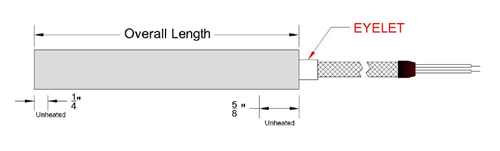

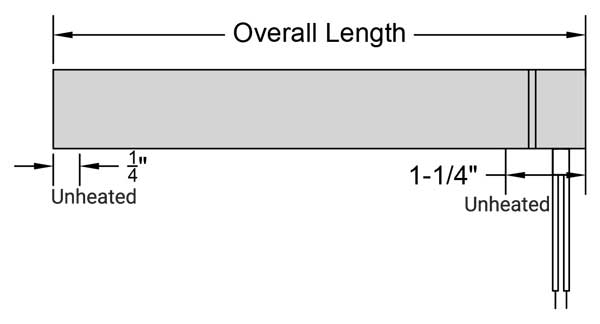

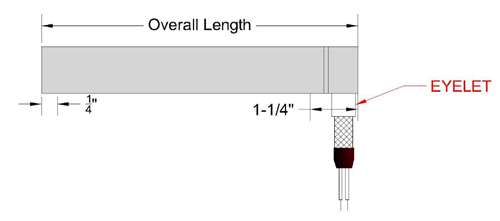

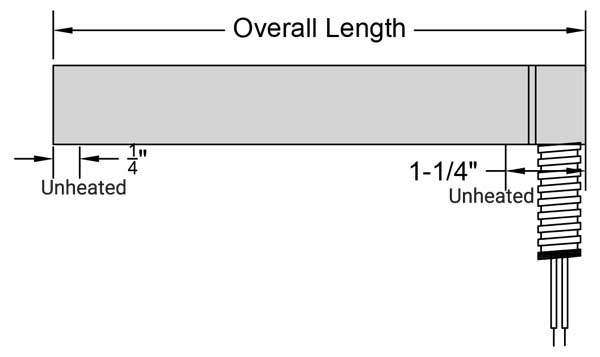

Thermal Corporation’s cartridge heaters offer a high watt density swaged construction including solid nickel electrical conductors exiting through a lava end plug. Flexible, stranded, high temperature lead wire is fused to the end of the solid conductors and durable fiberglass is used as insulation. If you require your leads to be flexible as soon as they exit the unit, specify swaged leads when ordering. Maximum internal temperature of our incoloy sheathed cartridge heater is 1700ºF. Close uniform spacing (less than 1/16″) between resistance wire and the sheath of the cartridge heater results in more efficient heat transfer, cooler elements, and longer lifetime. Swaging the heater after assembly compacts the insulation material, which increases the heat conduction away from the element, and holds the wire in exact position.

Ready to Order? Click here to request a quote by selecting Cartridge Heater from the Select a Product drop-down! Prices from $24.49.

| Standard Diameters available for fast shipment are: | |

|---|---|

| Inches | Millimeters |

| 1/4″ (.246" ± .002") | 6.5mm (.252" ± .002") |

| 5/16" (.309" ± .002") | 8mm (.311" ± .002") |

| 3/8″ (.371″ ± .002″) | 10mm (.389" ± .002") |

| .487" (.487" ± .002") | 12mm (.468" ± .002") |

| 1/2″ (.496″ ± .002″) | 12.5mm (.488" ± .002") |

| 5/8″ ( .621″ ± .002″) | 14.7mm (.574" ± .002") |

| 11/16″ (.683″ ± .002″) | 15mm (.586" ± .002") |

| .724" (.724" ± .002") | 16mm (.625" ± .002") |

| 3/4″ (.746″ ± .002″) | 16.5mm (.645" ± .002") |

| 7/8″ (.871″ ± .002″) | 18mm (.705" ± .002") |

| 1″ (.996″ ± .002″) | 18.5mm (.724" ± .002") |

| 20mm (.783" ± .002") | |

| 25mm (.980" ± .002") | |

| Tolerances and Recommended Voltages |

|---|

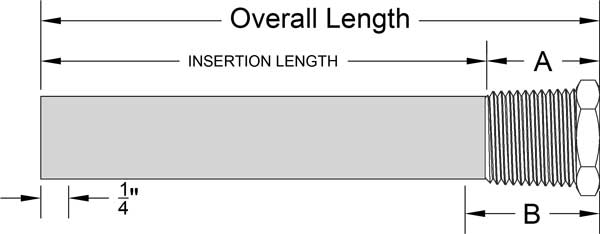

| Length Tolerances +/- 2% with +/- .09375" minimum tolerance. |

| Special Length Tolerances +/- 1.2% with +/- .09375" minimum tolerance |

| Maximum Lengths 1/4" diameter: 36" 3/8" diameter: 60" All others: 72" |

| Camber Tolerances Up to 12" long: 0 .010" Over 12": .020" per foot of length |

| In longer lengths, the camber should not affect usage as the cartridge heater will flex enough to accommodate installation in most machined holes. |

| Resistance Tolerances In designing both cartridge and band heaters, we calculate the required element resistance at 600 degrees Fahrenheit. This resistance is 6% higher than a room temperature of 72 degrees (F). The tolerance allowed on the total heater resistance is +10 / -5%. |

| Special Resistance Tolerance is +/- 5%. |

| Maximum Voltage Recommendations Diameters less than .5": 240V .5" Diameter and greater: 480V |

| Lead Length Tolerances +/- 1" up to 72" +/- 2% over 72" |

_______________________________________

Procedure for Sizing Cartridge Heaters for Heating Metal Parts

- Establish a maximum temperature at which the part will operate.

- Determine total wattage needed to produce this temperature.

- Establish the largest diameter and the length of the cartridge heater that is best suited to the dimensions of your part.

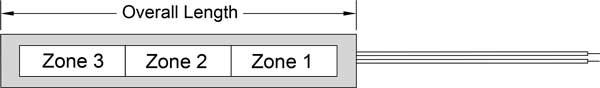

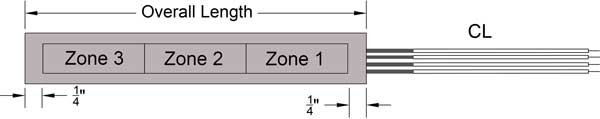

- Estimate the number of heaters needed for even heat. Divide the total wattage by the number of cartridge heaters to determine the wattage rating of each heater.

- Determine the watt density of the size selected (3.14 * diameter * length = area. Wattage / Area = watt density).

- Determine fit (subtract minimum outside diameter of the heater from maximum inside diameter of hole).

- If you find that the watt density is excessive, you can correct it in one of three ways:

- Use a tighter fit.

- Use more or larger heaters.

- Use a lower wattage and allow for a longer start up time.

_______________________________________

Installation Tips

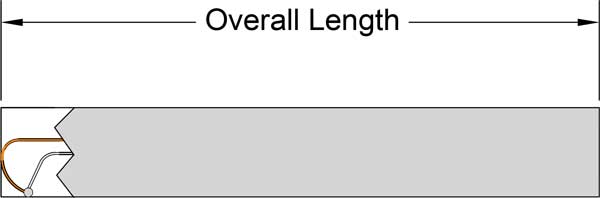

Cartridge Heaters Should Not Enter The Holes

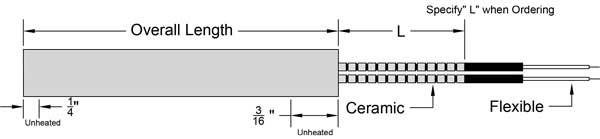

While the heater itself can withstand very high temperatures, the lead wire and connection to the pin wire cannot. The lead wire on our standard cartridge heater is rated to either 482°F or 842°F depending on the wattage and voltage. If your leads are going to be exposed to temperatures of over 500 degrees F, we suggest using our configuration CB which utilizes ceramic beads over nickel pin wire for excellent high temperature protection.

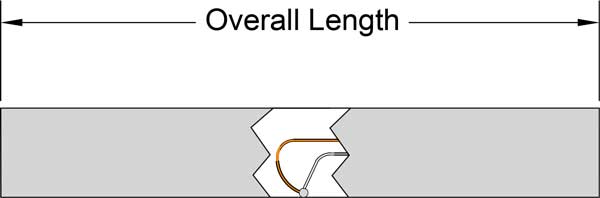

Cartridge Heaters Should Not Extend Outside The Holes

One of the reasons cartridge heaters usually have higher watt densities than other heaters is that their installation usually is in such a way that the heat is usually removed quickly from the surface of the heater. If your cartridge heater is extending out of the hole, you only have the surrounding air to remove the heat being generated by the heater. Of course, metal is a much better conductor of heat than air.

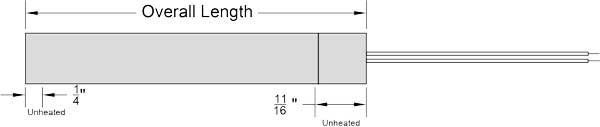

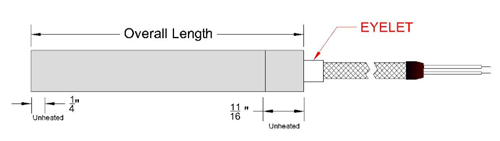

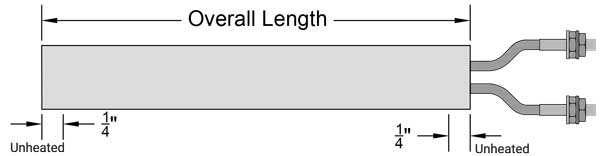

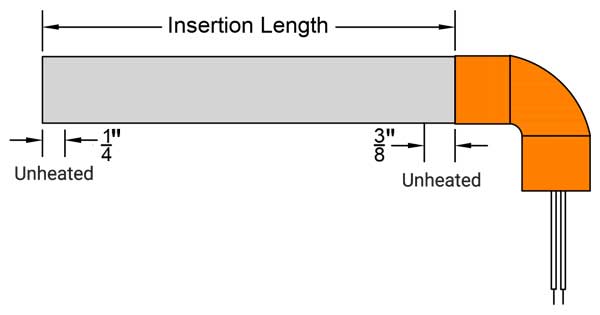

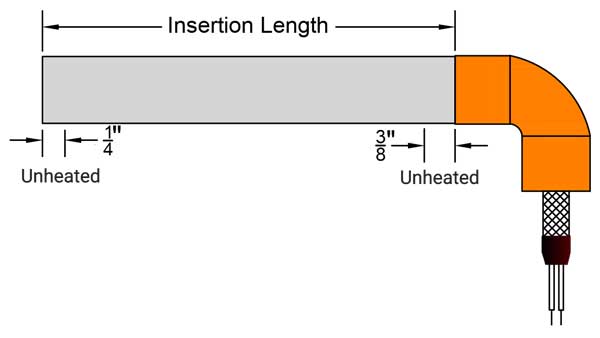

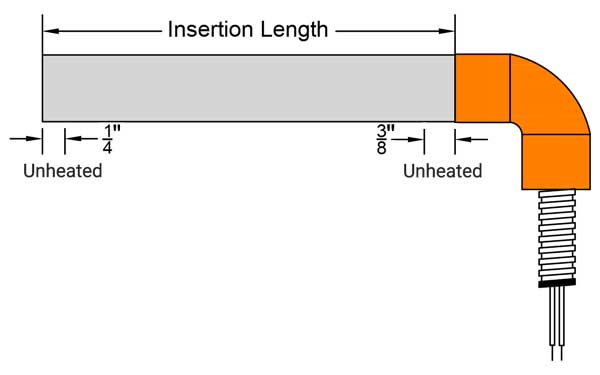

This can cause an early death for a cartridge heater. If you have to have a portion of your heater extending past the edge of the mounting hole, make sure you specify an unheated area at the end when ordering.

_______________________________________

Removal Tips

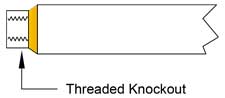

When using a rod as a “knock-out” tool, use one that is close to the same diameter as the cartridge heater.

When the cartridge heater has seized and is difficult to remove, some people use a rod to punch the heater out. If the rod is too small, it can cause the heater end to mushroom and scar the mold.

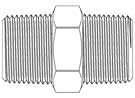

Thermal Corporation also recommends the use of a release and heat transfer agent such as Ease-Aid to help avoid your cartridge heaters from seizing. Another alternative is to use a threaded fitting such as Thermal’s Configuration TF (Cartridge Heater Option) available in brass or stainless.

_______________________________________

5 Common Causes of Cartridge Heater Failures and Tips for a Longer Heater Life

- Contamination: Hydraulic fluids, material and moisture have shortened the lives of more cartridge heaters than just about anything else out there. In instances where contamination cannot be avoided, there are lead configurations that can help retard the contamination entering the heater and often, if there is a moisture problem, you can run the heater at a reduced voltage for a few minutes to reduce the chance of the element shorting to the sheath when you apply full power.

- Lead Failure Due To Heat: Our standard leads are only rated to 700 degrees Fahrenheit under optimum conditions. This rating decreases with higher amperages, so often, reducing the wattage or increasing the voltage will solve the problem or you can use the CB cartridge heater configuration which utilizes ceramic beads over the pin wires as insulation.

- Lead Failure Due To Excessive Movement: The first, easiest and least expensive fix for this is to use swaged leads rather than crimped leads. The swaged leads are connected internally and are able to withstand bending from the point of exiting the cartridge heater while the crimped lead configuration has a solid nickel pin wire exiting the cartridge heater to which the stranded lead wire is crimped and then covered with a high temperature boot for insulation. Another possible fix is to use flexible stainless steel hose which retards the ability of the wire to make repeated sharp bends.

- Improper Usage: As discussed earlier, if there is a heated part of the cartridge heater exposed to air while the rest is inserted in something conducting the heat away, the heater will fail prematurely. If you need to have a section of the heater exposed, you can specify a cold section when ordering your cartridge heater.

- Wattage or Amperage Too High: This is pretty straightforward. The lower the watt density, the longer your cartridge heaters will function. There’s always a trade-off with start up time and heater life.

_______________________________________

Looking for an Alternate Covering Over the Leads?

We have two more options!

Silicone Boot

The silicone boot is an extremely flexible silicone coated fiberglass braid. May be added over both leads or to each of the lead wires for protection against abrasive applications and/or handling. It is also resistant to moisture. Should not be used if leads are exposed to temperatures of 380°F or more!

Ex Flex

The ex flex is a fiberglass sleeving impregnated with dielectric film of resin. It is not as flexible as the silicone boot, and can only withstand temperatures of 300°F. It does provide great dielectric strength to withstand severe applications and/or handling.

*Some customers prefer to use both. In which case we will attach the silicone boot and then the ex flex is attached over the boot.

_______________________________________

Related Blogs

What is a Split Sheath Cartridge Heater?

Tips for Extending the Life of Cartridge Heaters

What is Watt Density and How is it Related to Heater Life?

How To Apply Ease-Aid for Cartridge Heaters (video blog)

How To Correctly Insert a Cartridge Heater Into a Mold (video blog)

How To: Extend the Life of Cartridge Heaters (video blog)

Written by Jennifer Taylor & Shelby Reece

Date Published: 05.21.2014

Last Updated: 03.11.2020