Case Study #001: The Low Wattage-High Voltage Problem

Home > Blog Archive > Category: Case Studies > Case Study #001: The Low Wattage-High Voltage Problem

Case Study #001

This case study was the first of many to come, recorded on May 24, 1996, by Thermal Corporation engineer, Jim Dixon. Over the last fifty years, the great team of Thermal Corporation employees has helped many countless customers with heating applications. One of the byproducts of being an established company is having an extensive library of past solutions to lean on.

A customer sent in the following quote for a cartridge heater:

Diameter: 1/4″

Length: 1-1/2″

Lead Length: 20″

Watts: 75W

Volts: 208V

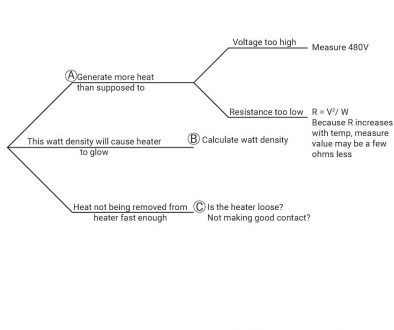

When we entered the quote into our tech sheet program, the program was unable to choose an internal resistance wire for these specific cartridge heater values. This caused us to ask three questions:

- Why is this a problem?

- If the program could pick a wire, why would this probably not be a good heater?

- What would we recommend?

Think About the Formula for Wattage

To begin, think about the formula for wattage.

Wattage = Current x Voltage

Heaters that have low wattage and relatively high voltage are typically a problem. If wattage is low and voltage is high, then what is the current? The current would be very low. How do you make a current very low?

I (Current) = E (Voltage) / R (Resistance)

OR

R = E / I

If the current is low and the voltage is high, what does R need to be? R needs to be very high. How do you make the resistance high? Think of electricity as water flowing through a heater. What diameter water hose has high resistance to the flow of water? A very small diameter hose will resist the flow of water. Thus, we have to use a very small wire and a LOT of it. In this case, we did not have any wire on hand that was small enough to make this particular case work.

Why Would This Not Be a Good Heater?

This leads into our second question: if we did have a small enough wire, why would this not be a good heater?

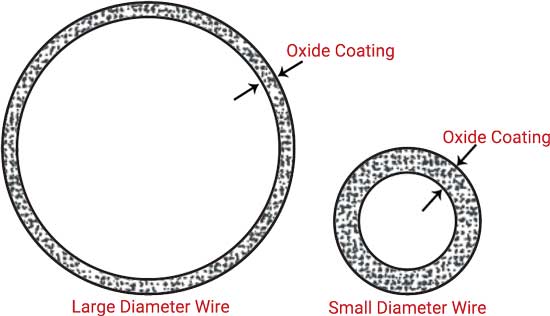

Remember that as heaters age, an oxide coating builds up on the surface. Temperature cycling accelerates this. Under a certain set of circumstances, the nickel-oxide will build up a constant rate. At some point, the oxide coating cuts off the path for electricity to flow- just like cholesterol clogging up an artery.

The oxide coating on each wire is the same thickness. So, which size do you think would fail first? If you thought the small wire, then you are correct.

What Would We Recommend?

Now, to address the question of what should be recommended. First of all, to cause the wire size to increase, what needs to be changed and how? The answer is the resistance must decrease.

W = E 2 / R

If W does not change, and R goes down, what happens to E? E must also go down, as well. This means the customer must go to a lower voltage.

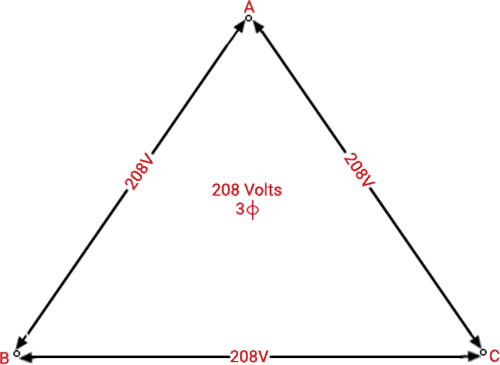

208 Volts, 3 phase power, is common in small industrial plants.

If 208V is a voltage from one hot-line to another hot-line, what is the voltage from a hot-line to the ground?

Line to Ground Voltage = Line to Line Voltage / √3 = 120V

Therefore, wherever there is 208V there is probably 120V, also. If we recommend 120 volts, how much does it help the resistance?

Initially:

R = E 2 / W

2082 / 75 = 577Ω

Now:

R = E 2 / W

1202 / 75 = 192Ω

Thus, resistance is decreased by a factor of 3. This is what we recommended to our customer.

Have a question about a heating application?

Contact the Thermal Corporation engineers! We can help you solve any issue or any question you may have regarding your heating application. Get in touch with us by email at engineering@thermalcorp.com, by phone at (800) 633-2962 x152, or chat with us using the instant chat feature located at the bottom of the page.

Written by Jim Dixon

Edited by Shelby Reece and Kyle Otte

Date Published: 08.23.2019

Last Updated: 08.23.2019