Case Study #144: Checking Cartridge Heaters for Moisture

Home > Blog Archive > Category: Case Studies > Case Study #144: Checking Cartridge Heaters for Moisture

Case Study #144

The MgO used as an insulator in cartridge heaters is hygroscopic. That is, it will pull moisture out of the air. If enough moisture is pulled into the heater, then the heater can short out on start-up. The moisture reduces the dielectric strength of the MgO allowing the current to jump to the sheath. Most moisture is trapped inside of the heater as free water vapor. When the temperature inside the heater reaches 212°F, this water vapor turns to steam.

However, there may be a small part of the moisture that chemically combines with the MgO.

MgO + H2O = Mg(OH)2

This moisture requires a temperature of more like 500°F to break loose. It has been in my experience that the moisture we and our customers often deal with primarily is the free water vapor molecules.

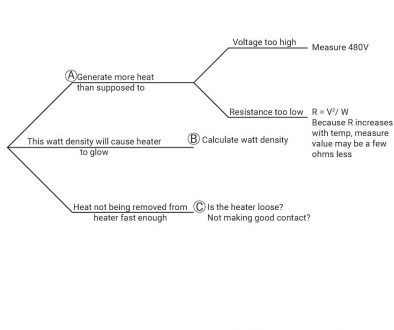

What happens is this…

![]()

As the temperature reaches 212°F, the water molecules become steam and begin making their way to the nearest exit, i.e., the lead end. The longer the heater, the more moisture likely to be inside of the heater. As the moisture begins to approach the lead end, it will reach the unheated section. At this point, the temperature may drop to below 212°F. The steam is then cooled to below 212°F and turns to liquid. The water disperses into the material at the lead end and, if enough is present, will permit the electricity to flow at least partly through the water from the leads to the sheath which will usually be grounded (0 volts) because the machine is grounded.

The higher the heater voltage, the less water is required to create the short. Also, the longer the heater, the more moisture can be absorbed by the heater. Thus, moisture is usually a problem with long 480V cartridge heaters that have been on the shelf open for a year or two.

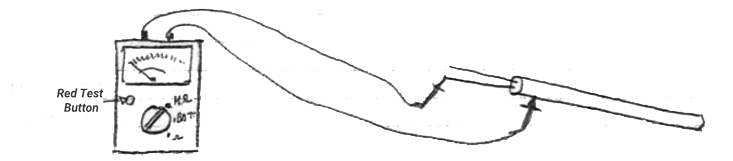

The best test for moisture– Amp Meg ohm meter

Set the meter to the MΩ scale and measure between the leads and sheath. Because the meter is measuring MΩ it uses a higher voltage than regular Ohm meters, so don’t touch the probes when doing the test or you could get shocked.

Touch sheath with one probe and leads with the other probe, then press the “red” test button. (It helps to have 3 hands.)

If the cartridge heater has moisture in it, the MΩ reading will be in the 10MΩ and 50MΩ+ range. If the heater has no moisture or has had the moisture driven out, the meter pointer will hardly move at all.

To drive the moisture out:

In the past, I have baked the heater for an hour at 300°F, then cracked the door of the oven and let the heater cool down slowly to continue driving out the moisture. If the heater is too long to fit in the oven, apply a lower voltage to the heater than the specified heater voltage, i.e., for a 480V heater, apply 120V. Set the heater on a bench in the lab until the heater gets hot but not until the sheath begins to turn light brown. Then, let the heater cool down on its own.

If you check these heaters again with the Meg ohm meter, the needle should hardly move.

Written by Jim Dixon and Shelby Reece

Edited by Kyle Otte

Date Published: 07.08.2019

Last Updated: 09.03.2019